Pamitundu yonse ya magalimoto, mabasi, mathirakitala ndi zida zapadera, ma valve solenoid amagwiritsidwa ntchito kwambiri kuwongolera kutuluka kwa zakumwa ndi mpweya.Werengani za ma valve a solenoid, momwe amapangidwira ndikugwira ntchito, komanso malo omwe amakhala pazida zamagalimoto m'nkhaniyi.

Kodi valavu ya solenoid ndi chiyani ndipo imagwiritsidwa ntchito pati?

Valavu ya solenoid ndi chipangizo cha electromechanical chowongolera kutali ndi kutuluka kwa mpweya ndi zakumwa.

Muukadaulo wamagalimoto, ma valve solenoid amagwiritsidwa ntchito pamakina osiyanasiyana:

- mu dongosolo pneumatic;

- mu hydraulic system;

- mu mafuta dongosolo;

- M'makina othandizira - pakuwongolera kutali kwa magawo otumizira, nsanja zotayira, zomata ndi zida zina.

Nthawi yomweyo, ma valve solenoid amathetsa ntchito zazikulu ziwiri:

- Kuwongolera kuyenda kwa sing'anga yogwirira ntchito - kuperekera mpweya wothinikizidwa kapena mafuta kumagulu osiyanasiyana, kutengera momwe amagwirira ntchito;

- Kulepheretsa kupezeka kwa sing'anga yogwirira ntchito pakagwa mwadzidzidzi.

Ntchitozi zimathetsedwa ndi ma valve a solenoid amitundu yosiyanasiyana ndi mapangidwe, omwe amafunika kufotokozedwa mwatsatanetsatane.

Mitundu ya ma valve solenoid

Choyamba, ma valve solenoid amagawidwa m'magulu awiri malinga ndi mtundu wa sing'anga yogwirira ntchito:

- mpweya - mavavu pneumatic;

- Madzi amadzimadzi - ma valve opangira mafuta ndi ma hydraulic system pazifukwa zosiyanasiyana.

Malinga ndi kuchuluka kwa kayendedwe ka sing'anga yogwirira ntchito komanso mawonekedwe ake, ma valve amagawidwa m'mitundu iwiri:

- Njira ziwiri - khalani ndi mapaipi awiri okha.

- Njira zitatu - kukhala ndi mapaipi atatu.

Mavavu anjira ziwiri ali ndi mapaipi awiri - polowera ndi potuluka, pakati pawo sing'anga yogwira ntchito imayenda mbali imodzi yokha.Pakati pa mapaipi pali valve yomwe imatha kutsegula kapena kutseka kutuluka kwa sing'anga yogwira ntchito, kuonetsetsa kuti imaperekedwa kumagulu.

Ma valve a njira zitatu ali ndi ma nozzles atatu omwe amatha kulumikizidwa wina ndi mnzake mophatikiza zosiyanasiyana.Mwachitsanzo, makina a pneumatic nthawi zambiri amagwiritsa ntchito ma valve okhala ndi polowera kumodzi ndi mapaipi awiri otulutsira, ndipo pamalo osiyanasiyana owongolera, mpweya woponderezedwa kuchokera ku chitoliro cholowera ukhoza kuperekedwa ku imodzi mwa mapaipi otulutsira.Kumbali ina, mu EPHX mavavu (yokakamiza idle economizer) pali mpweya umodzi ndi mipope iwiri yolowera, yomwe imapereka mpweya wabwino komanso kuchepetsa kupanikizika kwa carburetor idling system.

Ma valve anjira ziwiri amagawidwa m'mitundu iwiri molingana ndi malo omwe amawongolera pomwe ma elekitiroma amachotsedwa mphamvu:

- Nthawi zambiri kutsegulidwa (NO) - valavu ndi yotseguka;

- Kawirikawiri kutsekedwa (NC) - valve imatsekedwa.

Malinga ndi mtundu wa actuator ndi control, mavavu amagawidwa m'mitundu iwiri:

- Mavavu ochita mwachindunji - kuyenda kwa sing'anga yogwirira ntchito kumayendetsedwa ndi mphamvu yopangidwa ndi electromagnet;

- Ma valve oyendetsa ndege - kuyenda kwa njira yogwirira ntchito kumayendetsedwa pang'onopang'ono pogwiritsa ntchito kupanikizika kwapakati pawokha.

M'magalimoto ndi mathirakitala, ma valve osavuta ochita mwachindunji amagwiritsidwa ntchito nthawi zambiri.

Komanso, ma valve amasiyana ndi machitidwe ogwirira ntchito (voltage ya 12 kapena 24 V, bore mwadzina ndi ena) ndi mawonekedwe ake.Payokha, ndi bwino kutchula ma valve, omwe amatha kusonkhanitsidwa muzitsulo za zidutswa 2-4 - chifukwa cha malo ena a mipope ndi zomangira (eyelets), akhoza kuphatikizidwa mu dongosolo limodzi ndi chiwerengero chachikulu cha kulowa ndi mapaipi otulutsira.

Kapangidwe kake ndi mfundo yogwiritsira ntchito mavavu a solenoid

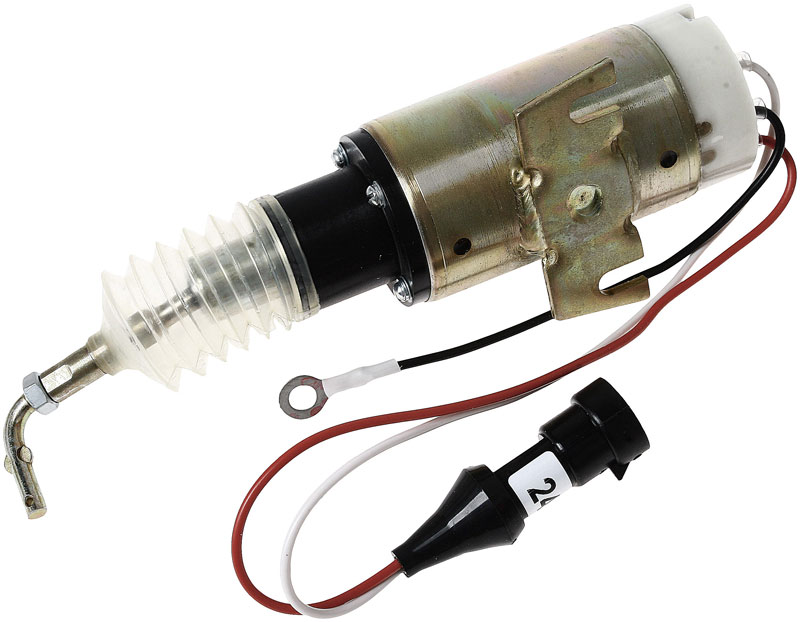

Ma valve onse a solenoid, mosasamala za mtundu ndi cholinga, ali ndi mapangidwe ofanana, ndipo ali ndi zigawo zingapo zazikulu:

- Electromagnet (solenoid) yokhala ndi zida zamapangidwe amodzi kapena ena;

- Control / kutseka chinthu (kapena zinthu) cholumikizidwa ndi armature ya electromagnet;

- Ma cavities ndi njira zoyendetsera sing'anga yogwirira ntchito, yolumikizidwa ndi zomangira kapena ma nozzles pathupi;- Corps.

Komanso, valavu imatha kunyamula zinthu zosiyanasiyana zothandizira - zida zosinthira kugwedezeka kwa akasupe kapena kugunda kwa chipangizocho, kukhetsa zopangira, zowongolera pamanja pakuyenda kwa sing'anga yogwirira ntchito, masiwichi owongolera zida zina kutengera boma. valavu, zosefera, etc.

Mavavu amagawidwa m'magulu atatu malinga ndi mtundu ndi kapangidwe ka chinthu chowongolera:

- Spool - chinthu chowongolera chimapangidwa mwa mawonekedwe a spool, omwe amatha kugawira kuyenda kwa sing'anga yogwirira ntchito kudzera munjira;

- Membrane - chinthu chowongolera chimapangidwa ngati membrane yotanuka;

- Pistoni - chinthu chowongolera chimapangidwa ngati pisitoni moyandikana ndi mpando.

Pankhaniyi, valavu ikhoza kukhala ndi chimodzi, ziwiri kapena zingapo zowongolera zomwe zimagwirizanitsidwa ndi chida chimodzi cha electromagnet.

Mfundo yogwira ntchito ya valve solenoid ndi yosavuta.Ganizirani za kagwiridwe kake ka diaphragm kosavuta kaŵirikaŵiri komwe kamakhala kotsekedwa komwe kumagwiritsidwa ntchito pamakina operekera mafuta.Valavu ikachotsedwa mphamvu, chidacho chimakanikizidwa motsutsana ndi diaphragm ndi kasupe, komwe kumatchinga njira ndikuletsa madzi kuti asapitirire kudutsa mudongosolo.Zomwe zimagwiritsidwa ntchito pa maginito amagetsi, mphamvu ya maginito imatuluka m'mphepete mwake, chifukwa chake chombocho chimakokedwa mkati - panthawiyi nembanembayo, yomwe siimakakamizidwanso ndi armature, imadzuka chifukwa cha kukakamizidwa kwa ntchitoyo. medium ndikutsegula njira.Ndi kuchotsedwa kotsatira kwaposachedwa kuchokera ku electromagnet, zida zomwe zimayendetsedwa ndi kasupe zidzabwerera kumalo ake oyambirira, kusindikiza nembanemba ndikuletsa njira.

Ma valve a njira ziwiri amagwira ntchito mofanana, koma amagwiritsa ntchito spools kapena pisitoni zowongolera zinthu m'malo mwa diaphragm.Mwachitsanzo, taganizirani mapangidwe ndi ntchito ya EPHX valve ya carburetor carburetor.Pamene maginito amagetsi amachotsedwa mphamvu, chombocho chimakwezedwa pansi pa zochitika za kasupe, ndipo chinthu chotseka chimatseka kumtunda, kulumikiza mbali ndi zochepetsera (mumlengalenga) - pamenepa, mphamvu ya mumlengalenga imagwiritsidwa ntchito ku EPHH. valavu ya pneumatic, imatsekedwa ndipo dongosolo la carburetor idling sikugwira ntchito.Zomwe zimagwiritsidwa ntchito pamagetsi amagetsi, zidazo zimachotsedwa, kugonjetsa mphamvu ya masika, kutseka kutsika kwapansi, ndikutsegula kumtunda, komwe kumagwirizanitsidwa ndi chitoliro cholowetsa injini (pomwe kuchepetsedwa kumawoneka) - pamenepa, a. vacuum imayikidwa pa EPHH valavu ya pneumatic, imatsegula ndikuyatsa dongosolo lopanda ntchito.

Mavavu a Solenoid ndi odalirika komanso osasamala pakugwira ntchito, ali ndi gwero lalikulu (mpaka mazana angapo ma actuations), ndipo, monga lamulo, safuna kukonza kwapadera.Komabe, pakagwa vuto, valavu iliyonse iyenera kusinthidwa mwamsanga - pokhapokha ngati ntchito yofunikira ndi chitetezo cha galimoto zidzatsimikiziridwa.

Nthawi yotumiza: Aug-24-2023