Injini iliyonse imakhala ndi zoyendetsa nthawi ndi mayunitsi okwera omangidwa pa lamba kapena unyolo.Kuti mugwiritse ntchito bwino pagalimoto, lamba ndi unyolo ziyenera kukhala ndi zovuta zina - izi zimatheka mothandizidwa ndi zida zolimbikitsira, mitundu, kapangidwe ndi kusankha kolondola komwe tafotokoza m'nkhaniyi.

Kodi tensioning device ndi chiyani?

Chipangizo champhamvu (chiwopsezo cha lamba, unyolo) - chida chothandizira kuyendetsa makina ogawa gasi (nthawi) ndi mayunitsi a injini zoyatsira zamkati za pisitoni;Makina omwe amakhazikitsa ndikusunga kukhazikika koyenera kwa lamba woyendetsa kapena unyolo.

Chipangizo cholimbitsa thupi chimagwira ntchito zingapo:

• Kuyika ndi kusintha kwa mphamvu yamphamvu ya lamba woyendetsa galimoto / unyolo;

• Kulipiridwa kwa lamba / kugwedezeka kwa unyolo komwe kumasintha chifukwa cha kuvala kwa magawo oyendetsa galimoto ndi kusintha kwa chilengedwe (kutambasula ndi kupanikizika kwa lamba / unyolo pansi pa kusinthasintha kwa kutentha ndi chinyezi, chifukwa cha kugwedezeka kwa katundu, etc.);

• Kuchepetsa kugwedezeka kwa lamba kapena unyolo (makamaka nthambi zawo zazitali);

• Pewani lamba kapena tcheni kuti zisadutse pamakina ndi magiya.

Ngakhale zida zolimbitsa thupi ndi zida zothandizira injini, zimagwira ntchito yofunika kwambiri - zimatsimikizira kugwira ntchito kwanthawi zonse kwa ma drive anthawi ndi mayunitsi okwera, motero gawo lonse lamagetsi limasinthasintha nthawi zonse.Choncho, pakagwa vuto, zipangizozi ziyenera kukonzedwa kapena kusinthidwa.Kuti mupange chisankho choyenera cha tensioner yatsopano, ndikofunikira kumvetsetsa mitundu yosiyanasiyana ya njirazi zomwe zaperekedwa lero, kapangidwe kake ndi mawonekedwe awo.

Mitundu ndi kugwiritsa ntchito kwa zida zolimbikitsira

Zipangizo zolimbitsa thupi zimagawidwa m'magulu malinga ndi cholinga chawo, kugwiritsa ntchito mtundu wina wagalimoto, mfundo yoyendetsera, njira yosinthira kupsinjika ndi magwiridwe antchito owonjezera.

Malinga ndi cholinga, ma tensioners ali amitundu iwiri ikuluikulu:

• Zoyendetsa nthawi;

• Kwa ma drive a mayunitsi okwera amagetsi.

Choyamba, chipangizochi chimapereka mphamvu yofunikira ya unyolo kapena lamba wa nthawi ya injini, chachiwiri - kugwedezeka kwa lamba wa mayunitsi kapena malamba a mayunitsi (jenereta, pampu yamadzi ndi fani), air compressor ndi ena).Ma tensioners angapo amapangidwe osiyanasiyana ndi cholinga amatha kukhazikitsidwa pa injini imodzi nthawi imodzi.

Malingana ndi momwe angagwiritsire ntchito, zida zowonongeka zimagawidwa m'magulu atatu:

• Zoyendetsa unyolo;

• Kwa amayendetsa pa V-lamba wamba;

• Kwa ma drive a V-nthiti.

Zovuta zamagalimoto osiyanasiyana zimasiyana pamapangidwe a chinthu chachikulu - pulley.Pazida zoyendetsa unyolo, gudumu la gear (sprocket) limagwiritsidwa ntchito, mu V-belt transmissions - V-pulley, mu polyclin drives - yofananira V-ribbed kapena yosalala pulley (malingana ndi njira yoyika chipangizocho ndi lamba - kuchokera kumbali ya mitsinje kapena kumbuyo kosalala).

Malinga ndi mfundo ya ntchito, tensioning zipangizo amagawidwa m'magulu atatu:

• Ma tensioners okhala ndi unsembe wokhazikika wa pulley;

• Zovuta za masika;

• Ma hydraulic tensioners.

Uliwonse wa mitundu ya zida zolimbitsa thupi uli ndi mawonekedwe ake, mitundu yawo ndi kapangidwe kake zikufotokozedwa pansipa.

Malinga ndi njira yosinthira mphamvu yamphamvu, zida ndi:

• Buku;

• Zokha.

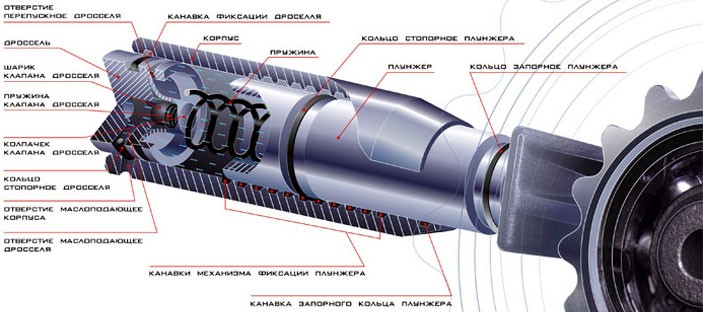

Mapangidwe a silinda ya hydraulic ya chipangizo cholumikizira nthawi

Pazida zamtundu woyamba, mphamvu yamagetsi imayikidwa (yosinthidwa) pamanja pakukonza kapena ngati kuli kofunikira.Wothandizira wosinthika nthawi zonse amakhala pamalo amodzi ndipo sangathe kubwezera mphamvu ya lamba / unyolo.Mtundu wachiwiri wa chipangizocho umasintha malo ake malinga ndi momwe zilili panopa, kotero kuti mphamvu ya lamba imakhala yosasinthasintha.

Potsirizira pake, zipangizo zowonongeka zimatha kuphatikizidwa ndi zipangizo zina ndikuchita ntchito zina zowonjezera - ndi zochepetsera unyolo, zochepetsera, ndi zina zotero.

Kupanga ndi mfundo yogwiritsira ntchito zida zolimbitsa thupi zokhala ndi unsembe wolimba wa pulley

Ma tensioners awa ali ndi mitundu itatu ya zida:

• Lever;

• Wopanda;

• Eccentric.

Chotchinga cha lever chimakhala ndi bulaketi yomwe imayikidwa mwamphamvu pa injini ndi cholumikizira chosunthika chokhala ndi pulley yoyikidwapo.Chophimbacho chimagwiridwa pa bulaketi ndi ma bolts awiri, ndipo imodzi mwa izo ili mu arcuate groove - ndi kukhalapo kwa poyambira komwe kumakulolani kuti musinthe malo a lever ndipo, motero, mphamvu ya lambayo.

Zipangizo zamtundu wa slide zimagwiritsidwa ntchito kwambiri: mwa iwo pulley sichimayikidwa pa lever, koma mumsewu wowongoka wa bracket, womwe umadutsa wononga (bolt).Pozungulira wononga, mutha kusuntha pulley motsatira poyambira, potero kusintha mphamvu ya lambayo.Pamene mphamvu yowonjezereka yofunikira ikhazikitsidwa, phulalo limawerengedwa ndi nati, kuonetsetsa kusasunthika kwa pulley.

Pamagalimoto onyamula anthu, zida zamagetsi zamagetsi zimagwiritsidwa ntchito nthawi zambiri.Mwamadongosolo, cholumikizira ichi chimakhala ndi chodzigudubuza chokhala ndi eccentric hub yokhazikika pamakina a injini kapena bulaketi.Mphamvu yamagetsi imasinthidwa ndikutembenuza chodzigudubuza kuzungulira nsonga ndikuyikonza pamalo osankhidwa ndi bolt.

Ma tensioners onse omwe amafotokozedwa ndi zida zosinthika pamanja zomwe zili ndi vuto lalikulu - sizingakwaniritse kusintha kwamphamvu kwa lamba.Kuipa uku kumathetsedwa mu kasupe ndi hydraulic tensioning zida.

Kupanga ndi mfundo ya kagwiritsidwe ntchito ka masika tensioning zida

Pali mitundu iwiri ya ma spring tensioners:

• Ndi kasupe wopondereza;

• Ndi kasupe wa torsional.

Pazida zamtundu woyamba, kusintha kwamphamvu kwa lamba kumachitika ndi kasupe wamba wopotoka, womwe umakanikiza bulaketi ndi roller / sprocket mpaka lamba / unyolo.Pazida zamtundu wachiwiri, ntchitoyi imachitika ndi kasupe wokhotakhota wambiri, wopindidwa ndi mphamvu inayake.

Torsional spring tensioners ndi omwe amagwiritsidwa ntchito kwambiri masiku ano - ndi ochepa, osavuta komanso odalirika.Chipangizo choterocho chimakhala ndi lever yokhala ndi pulley ndi maziko (chofukizira) chokhala ndi kasupe, kuti akhazikitse bwino, kasupe pa chipangizo chatsopano chotsitsimutsa kale amapanikizidwa ndi mphamvu yofunikira ndikukhazikika ndi cheke.

Chipangizo cholimbitsa thupi chokhala ndi torsion kasupe

Monga lamulo, zida zomangira masika zimagwiritsidwa ntchito pamagalimoto a lamba (V-ndi V-ribbed) a mayunitsi okwera, komanso pamayendedwe anthawi yamainjini onyamula anthu okhala ndi malamba anthawi.

Kupanga ndi mfundo yogwiritsira ntchito zida zamagetsi zamagetsi

Maziko a mtundu uwu wa tensioners ndi silinda ya hydraulic yomwe imakanikiza pulley / sprocket ku lamba / unyolo.Silinda ili ndi zibowo ziwiri zoyankhulirana, zolekanitsidwa ndi pulani yosunthika, yomwe imalumikizidwa ndi pulley / sprocket mothandizidwa ndi ndodo (kapena m'malo mwake, pachiwopsezo cha chipangizo cholumikizira chokhala ndi pulley / sprocket wokwera).Komanso mu silinda pali ma valve angapo odutsa madzimadzi ogwira ntchito.Pakatikati pa plunger, silinda imapereka lamba / unyolo wofunikira ndipo sizikhudza kuyendetsa galimoto mwanjira iliyonse.Pamene kukangana kwa lamba / galimoto kumasintha, plunger imasintha malo ake, madzimadzi ogwira ntchito amayenda kuchokera kumtunda umodzi kupita ku wina, kuonetsetsa kuti lambayo akuyenda bwino pamalo atsopano.Mitundu yosiyanasiyana yamafuta a injini imagwiritsidwa ntchito ngati madzi ogwirira ntchito.

Silinda ya hydraulic imatha kuyikidwa pa bulaketi kapena pa injini, mumayendedwe anthawi yayitali, ma silinda awiri amagwiritsidwa ntchito nthawi imodzi, iliyonse yomwe imagwira ntchito payokha.Ma cylinders atsopano ali ndi mphamvu yolimbikitsira, ndodo zawo zimakhazikika pamalo omwe akufuna ndi cheke.

Nkhani zakusankha, kukonza ndi kukonza zida zolimbikitsira

Pogwiritsa ntchito galimotoyo, zida zolimbitsa thupi zimatha kwambiri ndikutaya makhalidwe awo, choncho zimayenera kufufuzidwa nthawi zonse ndikusinthidwa.Ma tensioners okhawo omwe amavomerezedwa ndi wopanga injini ayenera kusankhidwa kuti alowe m'malo - apo ayi chipangizocho sichingayikidwe, kapena sichidzapereka mphamvu yofunikira ya lamba kapena unyolo.

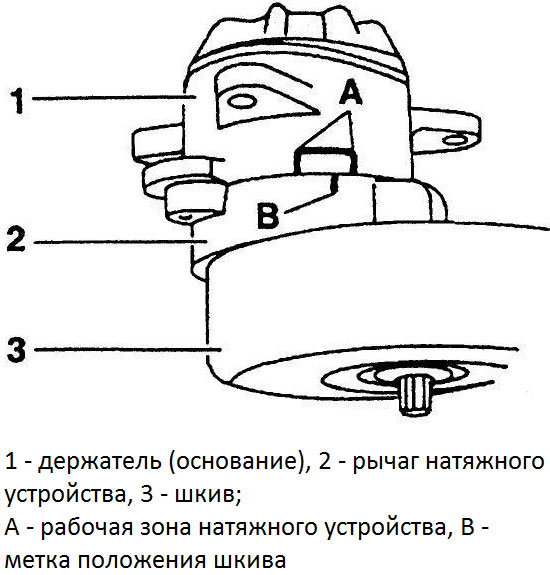

Zipangizo zomangira lamba zamagawo okwera ndizokhazikika kwambiri ndipo zimatha kugwira ntchito kwa zaka zambiri, ziyenera kusinthidwa ndikuwonongeka kwakukulu kapena kuwonongeka.The tensioner latsopano ayenera kuikidwa ndi kusintha mogwirizana ndi malangizo ntchito galimoto.Ngati chipangizocho chili ndi chiwongolero cholimba cha pulley, chiyenera kusinthidwa mwa kusintha malo a lever kapena kugwiritsa ntchito screw.Ngati chipangizocho chiri masika, ndiye kuti chiyenera kukhazikitsidwa poyamba, ndiyeno chotsani cheke - pulley yokha idzagwira ntchito.Pankhaniyi, m'pofunika kuonetsetsa kuti chizindikiro pa lever kugwera m'dera m'munsi mwa chipangizo, apo ayi muyenera kusintha lamba kapena kuona serviceability wa tensioner.

Kuyika kolondola kwa chipangizo cholimbitsa mphamvu molingana ndi zikhomo

Zipangizo zomangika za ma drive chain chain nthawi zambiri zimasinthidwa kwathunthu ndi unyolo, ma dampers ndi zida zina.M'malo mwa zigawozi ziyenera kuchitika mosamalitsa ndi malangizo a malangizo.Zovuta zamtunduwu sizifunikira kusintha, ziyenera kukhazikitsidwa ndikuchotsedwa pa cheke - sprocket itenga malo ogwirira ntchito ndikuwonetsetsa kuti unyolo ukuyenda bwino.

Ndi kusankha koyenera ndikusintha ma tensioners, zoyendetsa nthawi ndi mayunitsi azigwira ntchito modalirika pazifukwa zilizonse.

Nthawi yotumiza: Aug-05-2023